AS9100 Aerospace Quality Standard

HRGQ has been AS9100 Rev.D certified since 2015. Mainly focused on aerospace, HRGQ has been providing product used on most models of Airbus and Boeing aircraft.

NAPCAP Accredited Company

Click here to learn more about Nadcap certifications

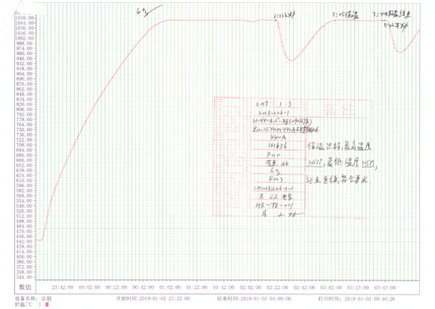

HRGQ has been NADCAP accredited since 2017 for Heat Treatment. We current have three high-temp furnaces which certified from 500℃ to 1100 ℃ , one tempering oil tank and two deep-freeze equipment. All furnaces and tempering tank were designed by HRGQ and patent registered.

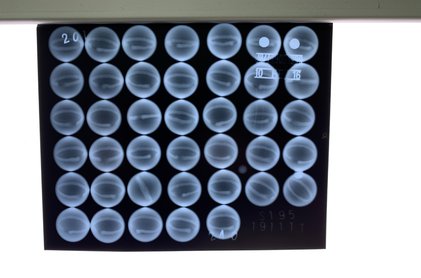

(Deep-Freeze Equipement, Balls are being cold-treated at -80℃)

(Deep-Freeze Equipement, Balls are being cold-treated at -80℃)

Manufacturing and Testing Ability

HRGQ has fully manufacturing capability in house for both hollow ball and solid ball product.

|

|

| (Click to Enlarge) | (Click to Enlarge) |

|

|

|

|

HRGQ has the following testing capabilities in house:

-

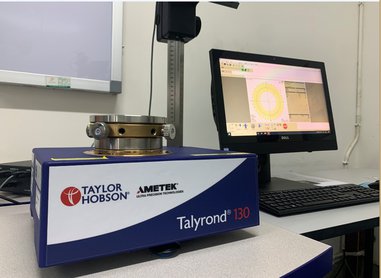

Roundness tester (Talyrond)

-

Waviness tester (Talyrond)

-

Surface roughness tester (Accretech)

-

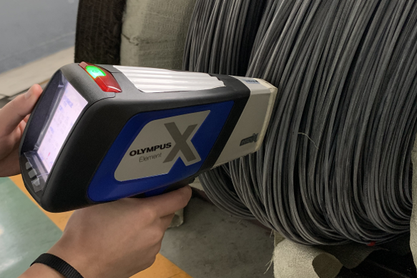

Chemical analysis (Olympus)

-

Rockwell hardness tester (Nadcap accredited)

-

Vickers/Knoop Hardness tester for microhardness

-

Metallurgical Microscope (Leica)

-

Diameter Comparator (Mahr)

-

Eddy Current Tester (Aviko)

-

Static load tester

-

Hollow ball impact tester

-

Electromagnetic material sorting machine

|

|

|

|

|

|

|

|

|

|

Patents

HRGQ is not just a manufacture but also an engineering company that design process, equipment and product to meet customers’ need. We currently have tens of registered patents for inventions we utilized in production and managing.

Reliable Supply Chain

HRGQ offers a full range of materials including 400-series,300-series stainless steel, 2205 duplex steel, 52100 ball bearing steel, carbon steel, ceramic, and brass. Also has pure niobium, Molybdenum and silicon materials balls.

We source and stock material from mills and manufactures all over the world. Material that meet DFARS requirement and AMS/ASTM Standards.

Major Steel/Ceramic Supplier

All material is subject to incoming inspection before release to production.

People Focused

HRGQ understands People is the most valuable asset to organization. We are proud to have people from different background and expertise to work together and delivery satisfied product to our customers. “Respect of People” has been a vital mind-set that implant into everyone works for HRGQ.

- VALUES: Quality, Productivities, Team Work, People Focus, Customer Oriented

- MISSION: To make the world more productive and sustainable with our knowledge and products

- VISION: Be the global leader in precision balls